-40%

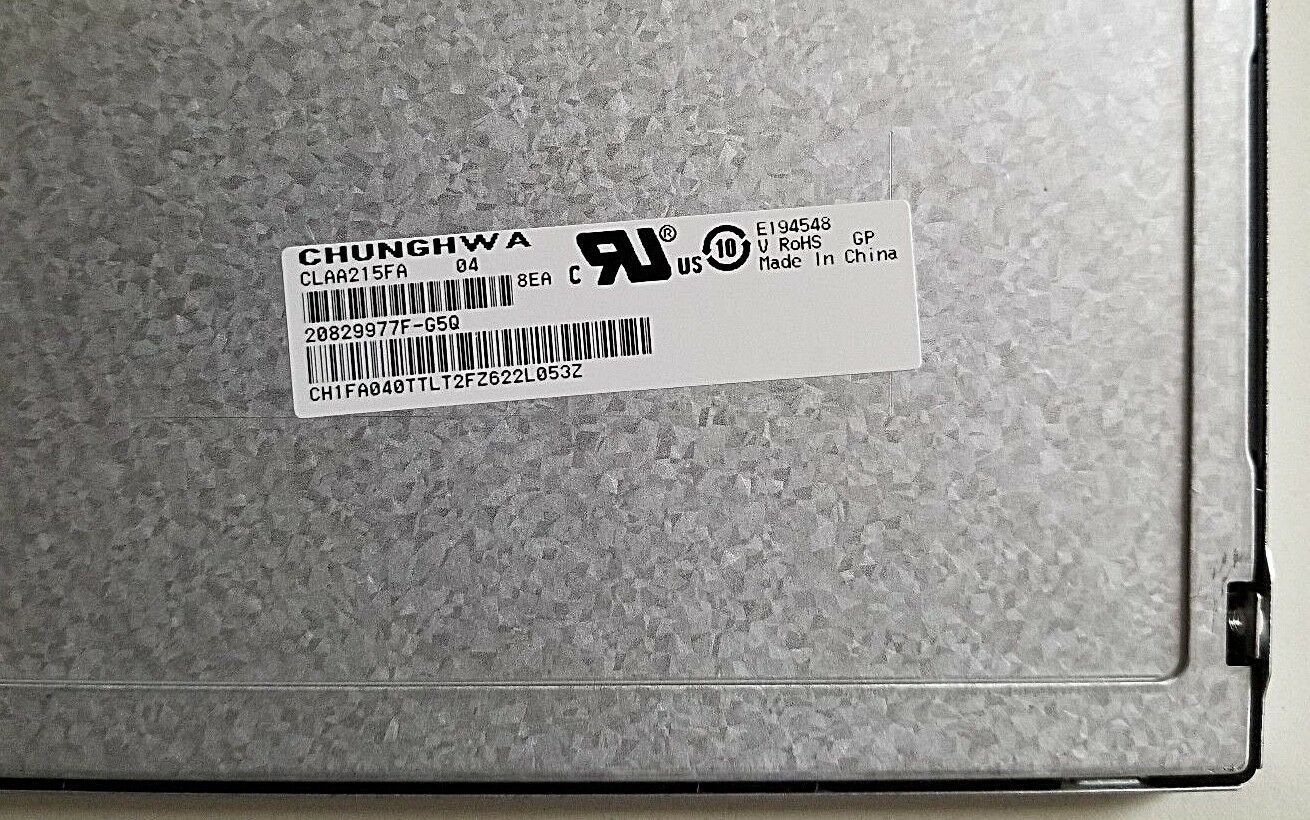

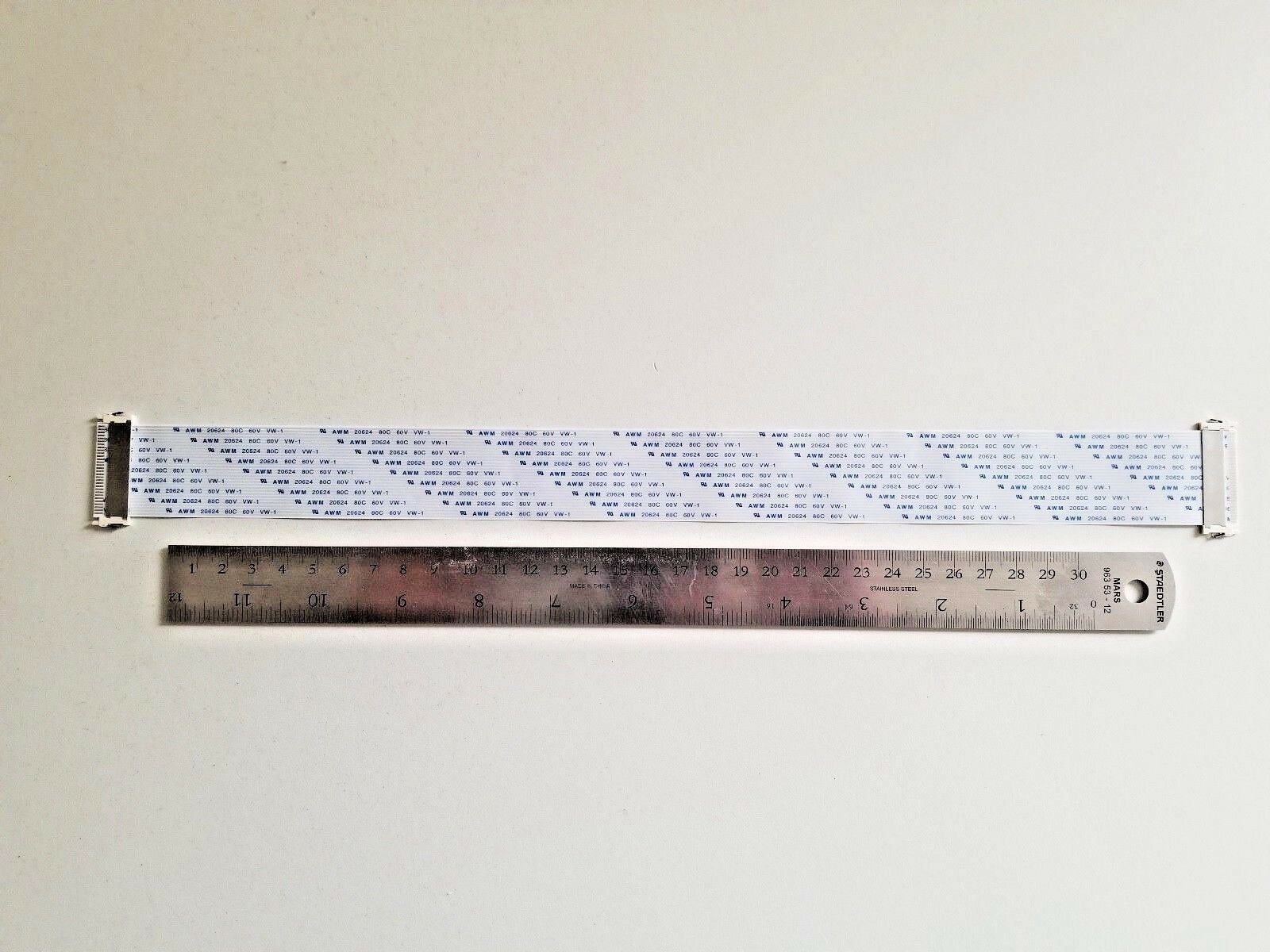

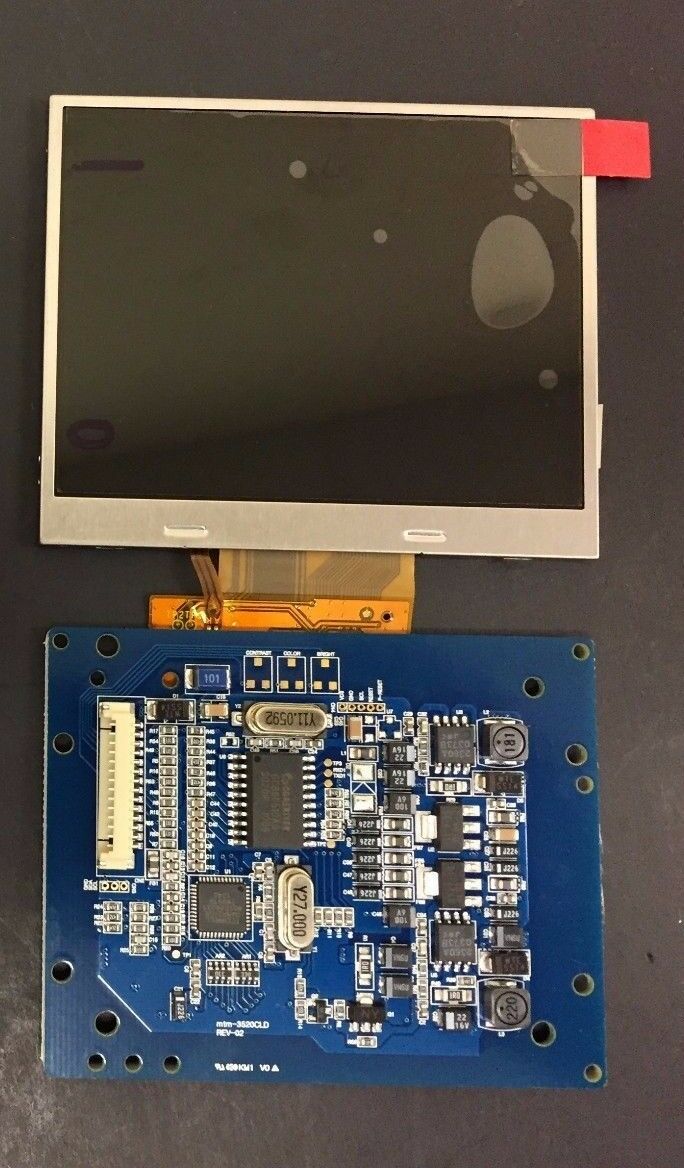

Chungwa 21.5" TFT-LCD Panel (CLAA215FA-04) w/ LVDS & power cable (lot pricing)

$ 242.35

- Description

- Size Guide

Description

PANEL DETAILPanel Size :21.5 inch

Panel Type :a-Si TFT-LCD

Composition :LCM

Resolution :1920×1080

Mode :TN, Normally White, Transmissive

Surface :Antiglare, Hard coating (3H)

Brightness :250 cd/m² (Typ.)

Contrast Ratio :1000:1 (Typ.)

Display Color :16.7M

Viewing Angle :85/85/80/80 (Typ.)(CR≥10)

Frequency :60Hz

Lamp Type :10S8P×2CN WLED

Signal Type :LVDS (2 ch, 8-bit)

Datasheet :

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Chunghwa Picture Tubes, Ltd.

Technical Specification

To : HUI YING TUNG ELECTRONIC CO., LTD

Date : 2011/02/15

ACCEPTED BY

Prepared by: Design Division

CHUNGHWA PICTUER TUBES, LTD.

No. 1, Huaying Rd., Sanho Tsun, Lungtan Shiang, Taoyuan, Taiwan, 325, R.O.C.

TEL: +886-3-4805678 FAX: +886-3-4800589

Doc. No:

SPEC-CLAA215FA04_V4-HUIYING-Ver.4

Issue Date: 2011/02/15

CPT TFT-LCD

CLAA 215FA04

APPROVED BY CHECKED BY PREPARED BY

Kevin Chen Tristan Wang

Product Planning

Management

Division

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

2

Datasheet Version.: 01

Table of Content

NO Table of Content Note

1 OVERVIEW P.3

2 ABSOLUTE MAXIMUM RATINGS P.4

3 ELECTRICAL CHARACTERISTICS P.5

4 INTERFACE PIN CONNECTION P.8

5 INTERFACE TIMING P.9

6 BLOCK DIAGRAM P.12

7 MECHANICAL SPECIFICATION P.13

8 OPTICAL CHARACTERISTICS P.15

9 RELIABILITY TEST CONDITIONS P.18

10 DESIGNATION OF LOT MARK P.19

11 PACKING SPECIFICATION P.20

12 HANDLING PRECAUTIONS FOR TFT-LCD MODULE P.22

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

3

Datasheet Version.: 01

1. OVERVIEW

CLAA215FA04_V4 is 21.5” color TFT-LCD (Thin Film Transistor Liquid Crystal Display) module

composed of LCD panel, driver ICs, control circuit and backlight. By applying 6bits+Hi-FRC digital data,

1920Å~1080, 16.7M-color images are displayed on the 21.5” diagonal screen. Input power voltage is 5.0V

for LCD driving. Converter for backlight is not included in this module. General specification is

summarized in the following table:

ITEM SPECIFICATION

Display Area(mm) 476.64 (H) Å~ 268.11 (V) (21.53-inch diagonal)

Number of Pixels 1920 (H) Å~ 1080(V)

Pixel Pitch(mm) 0.24825 (H) Å~ 0.24825 (V)

Color Pixel Arrangement RGB vertical stripe

Display Mode Normally white, TN

Number of Colors 16.7M(6bits+Hi-FRC)

Brightness(cd/m^2) 250cd/m

2

(Typ.)(center, 60mA)

Viewing Angle(H/V) 170/160 (Typ.)

Surface Treatment Anti-glare, 3H

Power consumption(W) 17.5W Without Converter(Typ.)

Module Size(mm) 495.6 (W) Å~ 292.2 (H) Å~9.85(D) (Typ.)

Module Weight(g) 1830g(Typ.)

Backlight Unit LED (White-LED)

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

4

Datasheet Version.: 01

2. ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN. MAX. UNIT REMARK

Power Supply Voltage for LCD VCC 0 6 V

LED Forward voltage V

F

2.9 3.6 V

LED Forward current I

F

57 63 mA

1). 2)

Operation Temperature Top 0 50 3). 4). 5). 7)

Storage Temperature Tstg -20 60 3). 4). 5). 7)

[Note]

1).Product life-time relate to LED, please operate production follow statement at page 8 (2)back

light.

2).When LED current over the definition of operating current ,product life-time will decay rapidly or

operate unusual.

3)The relative temperature and humidity range are as below sketch, 90%RHMax.(Ta40).

4).The maximum wet bulb temperature 39(Ta40) and without dewing.

5).If you use the product in an environment which over the definition of temperature and humidity too

long to effect the result of eye-etching.

6) Test Condition: IEC 1000-4-2 VESDt: Contact discharge to input connector; VESD

C

: Contact

discharge to module

7). If you operate the product in normal temperature range, the center surface of panel should be under

60.

0 20 40 60

-

20

20

40

60

80

5

90

50

Operating Range

Storage Range

Relative humidity(%RH)

Temperature (°C)

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

5

Datasheet Version.: 01

3. ELECTRICAL CHARACTERISTICS

(1).TFT-LCD Ta=25

ITEM SYMBOL MIN TYP MAX UNIT REMARK

Power Supply Voltage for LCD VCC 4.5 5.0 5.5 V *1)

Power Supply Current for LCD ICC -- 1050 1950 mA *2)

Permissive Ripple Voltage for Logic VRP -- -- 100 mVp-p VCC=5.0V

Differential Resistance Zm 90 100 110

The same motion input Voltage VCM 1.125 1.25 1.375 V

Differential input Voltage VID 200 350 600 mV

High electric potential threshold

voltage VTH - - 100 mV

LVDS:

IN+INLow

electric potential threshold

voltage VTL -100 - - mV

*3)

LCD Irush Current Irush - - 4 A *4)

Power consumption P - 5 11 W *2)

[Note]

*1)Powerdata sequence

0.50mst110ms t41 sec

0.01mst250ms t5200ms

0.01mst350ms t6200ms

data

t1 t2 t3

4.5V 4.5V

0.5V

Vin=5.0V

0.5V 0.5V

t4

LCD Power Supply

Logic Signal

t5 t6

Backlight Power Supply

VL

Data: RGB DATA, DCLK, DENA

VCC-dip conditions:

(1) When 3.6VVcc(min)<4.5V: td10 ms

(2) When Vcc <3.6 V, VCC-dip conditions should also follow the VCC-turn-on conditions.

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

6

Datasheet Version.: 01

2).

Typical value is measured when displaying horizontal gray scale line pattern:

64 gray level, 1920 line mode

VCC=5.0 VfH= 67.8 kHzfV=60 HzfCLK=72 MHz

Maximun value is measured when displaying 2 line pattern:

VCC=5.0 VfH= 66.9 kHzfV=75 HzfCLK=90 MHz

*

3) LVDS Signal definition

VIN+Positive differential DATA & CLK Input

VIN- Negative differential DATA CLK Input

*4).Irush Measurement Condition

(2).Backlight

1. Electrical specification

1-1 single LED

Ta=25(

!

)

ITEM SYMBOL Min TYP MAX UNIT REMARK

Forward Voltage V

F

2.9 3.25 3.6 V I

F

=60mA

Forward Current I

F

57 60 63 mA 1)

Power consumption W 195 mW

I

F

=60mA

V

TH

V

TL

VID

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

7

Datasheet Version.: 01

1-2 CN2

Type Part Number

CI1406M1HRE-NH(CviLux)

or

compatible

Mating Housing Part Number

CI1400SL000-NH(CviLux)

Pin Name Description

1 LED_04 String 16PcsLEDfeedback 60mA

2 LED_03 String 16PcsLEDfeedback 60mA

3 VLED+ VLED+4Parallel 16String ; 64Pcs LED

4 VLED+ VLED+4Parallel 16String ; 64Pcs LED

5 LED_02 String 16PcsLEDfeedback 60mA

6 LED_01 String 16PcsLEDfeedback 60mA

2. life time

ITEM min Typ max UNIT REMARK

LIFE TIME 30000 -- -- hrs 2"#"$"%"

[Note]

1).If dimming function is required, it is strongly recommended to adopt pulse width modulation

(PWM).If not, linear decrease of the driving current will affect the optical characteristics

2).Parameter guideline for LED driving is under stable conditions at 25& (Room Temperature) and

'

()*

mA

3). Definition of the lamp life time: Luminance (L) under 50% of specification.

4). When the ambient temperature Ta overstep 25&, it will serious damage life time.

5). When the LED operation current

'

overstep 60mA, it will serious damage life time.

CN2 LIGHTBAR

Pin 1

CN1:LVDS

BACK of MDL

Pin 6

Pin 1 Pin 30

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

8

Datasheet Version.: 01

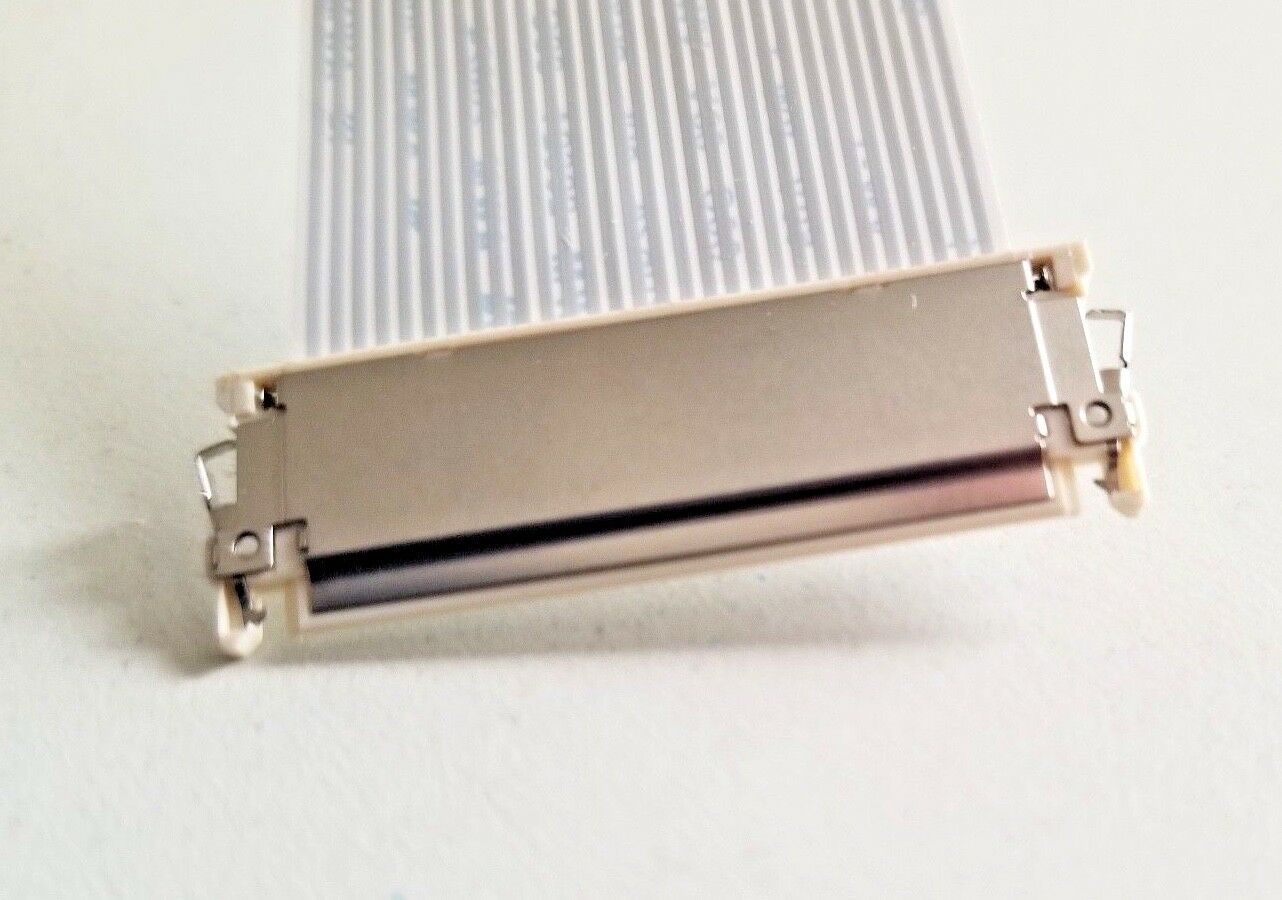

4. INTERFACE PIN CONNECTION

(1) CN1

Type Part Number

0930G30-B2001A-M4(STARCONN) /

MSCKT2407P30H(STM) or compatible

Mating Housing Part Number

FI-X30HL

(JAE)

FI-X30H

(JAE)

PIN NO. REMARK FUNCTION

1 RXO0- minus signal of odd channel 0(LVDS)

2 RXO0+ plus signal of odd channel 0(LVDS)

3 RXO1- minus signal of odd channel 1(LVDS)

4 RXO1+ plus signal of odd channel 1(LVDS)

5 RXO2- minus signal of odd channel 2(LVDS)

6 RXO2+ plus signal of odd channel 2(LVDS)

7 GND GND

8 RXOC- minus signal of odd clock channel (LVDS)

9 RXOC+ plus signal of odd clock channel (LVDS)

10 RXO3- minus signal of odd channel 3(LVDS)

11 RXO3+ plus signal of odd channel 3(LVDS)

12 RXE0- minus signal of even channel 0(LVDS)

13 RXE0+ plus signal of even channel 0(LVDS)

14 GND GND

15 RXE1- minus signal of even channel 1(LVDS)

16 RXE1+ plus signal of even channel 1(LVDS)

17 GND GND

18 RXE2- minus signal of even channel 2(LVDS)

19 RXE2+ plus signal of even channel 2(LVDS)

20 RXEC- minus signal of even clock channel (LVDS)

21 RXEC+ plus signal of even clock channel (LVDS)

22 RXE3- minus signal of even channel 3(LVDS)

23 RXE3+ plus signal of even channel 3(LVDS)

24 GND GND

25 NC NC

26 NC Test pin (Can’t connect to GND)

27 NC NC

28 VCC Power supply input voltage(5.0 V)

29 VCC Power supply input voltage(5.0 V)

30 VCC Power supply input voltage(5.0 V)

1) Keep the NC Pin and don’t connect it to GND or other signals.

2) GND Pin must connect to the ground, don’t let it be a vacant pin.

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

9

Datasheet Version.: 01

5. INTERFACE TIMING

(1) Timing Characteristic

ITEM SYMBOL MIN. TYP. MAX. UNIT

DCLK Freq. f

CLK

55 72 90 MHz

Cycle t

CLK

18.18 13.89 11.11 ns

Horizontal effective time t

HA

960 960 960 t

CLK

Horizontal Horizontal blank time t

HB

40 100 160 t

CLK

Horizontal total time t

H

1000 1060 1120 t

CLK

Vertical frame Rate Fr 50 60 75 Hz

Vertical total time t

V

1090 1130 1230 t

H

Vertical effective time t

VA

1080 1080 1080 t

H

LCD

Timing

DENA

Vertical

Vertical blank time t

VB

10 50 150 t

H

[Note]

*1) DENA (data enable) usually is positive

*2) DCLK still inputs during blanking

*3) DE mode only

*4) It maybe cause flicker at 50Hz.

(2).Timing Chart

EVEN DATA

(R,G,B)

Invalid Data 1918 1920 Invalid Data

a. Horizontal Signal

DCLK

First Data

ODD DATA

5

(R,G,B)

Invalid Data 1917 1919 Invalid Data

Last Data

t

HB

t

HA

DENA

1 3 2 4 6

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

10

Datasheet Version.: 01

(3).LVDS Data

For 6Bit+Hi-FRC

b. Vertical Signal

t

VB

DENA

t

VA

LINE DATA

Invalid Data 1 3 3 1079 1080 Invalid Data

!"#$ % &" '

OG[0]

()*

!"#$ % &" '

EG[0]

()*

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

11

Datasheet Version.: 01

Color Data Assignment

R DATA G DATA B DATA

COLOR INPUT DATA R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

MSB LSB MSB LSB MSB LSB

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BLUE(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

CYAN 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

MAGENTA 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

YELLOW 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BASIC

COLOR

WHITE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RED(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(1) 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(2) 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(254) 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED

RED(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

GREEN(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

GREEN(254) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0

GREEN

GREEN(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BLUE(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

BLUE(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

BLUE(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

BLUE(254) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0

BLUE

BLUE(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

[Note] 1) Definition of gray scale: Color (n): n indicates gray scale level; higher n means brighter level.

2) Data: 1-High, 0-Low.

3)For odd & even data also.

(4).Color Data Distribution

D(1,1) D(2,1) .. D(X,1) .. D(1919,1) D(1920,1)

D(1,2) D(2,2) .. D(X,2) .. D(1919,2) D(1920,2)

.. .. + .. + .. ..

D(1,Y) D(2,Y) .. D(X,Y) .. D(1919,Y) D(1920,Y)

.. .. + .. + .. ..

D(1,1079) D(2, 1079) .. D(X, 1079) .. D(1919, 1079) D(1920, 1079)

D(1, 1080) D(2, 1080) .. D(X, 1080) .. D(1919, 1080) D(1920,1080)

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

12

Datasheet Version.: 01

6. BLOCK DIAGRAM

LVDS receiver 2ch

Timing

Controller

Light bar Unit in Backlight

Source Driver

LCD Panel

1920 X 3 X 1080

Gate Driver

Power Supply

Circuit

TFT-LCD Module

CN1 I/F Connector

6 Pin

Connector

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

13

Datasheet Version.: 01

7. MECHANICAL SPECIFICATION

(1) Front side (Tolerance is Å} 0.5mm unless noted) [Unit: mm]

(2)Rear side (Tolerance is Å}0.5mm unless noted) [Unit: mm]

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

14

Datasheet Version.: 01

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

15

Datasheet Version.: 01

8. OPTICAL CHARACTERISTICS

Ta=25VCC=5.0V

ITEM SYMBOL CONDITION MIN. TYP. MAX. UNIT REMARK

Contrast (CEN) CR θ=+0Åã 700 1000 -- -- *1) 2)

Luminance (CEN) L θ=+0Åã 180 250 -- cd/m2 *1) 3)

9P Uniformity ΔL θ=+0Åã 75 -- -- % *1) 3)

Response Time Tr+Tf θ=+0Åã -- 5 10 ms *5)

Cross talk CT θ=+0Åã -- -- 1 % *6)

Horizontal 150 170 -- Deg.

Vertical θ

CR

10

140 160 -- Deg.

Horizontal 150 170 -- Deg.

View angle

Vertical θ

CR

5

150 170 -- Deg.

*4)

White x 0.283 0.313 0.343

y 0.299 0.329 0.359

Red x (0.613) (0.643) (0.673)

y (0.323) (0.353) (0.383)

Green x (0.299) (0.329) (0.359)

y (0.599) (0.629) (0.659)

(0.124) (0.154) (0.184)

Color

Coordinates

Blue x

y

θ=+0Åã

(0.027) (0.057) (0.087)

Color

Coordin

ates

*3)

Gamut CG θ=+0Åã 68 72 -- %

Gamma VESA 2.0 2.2 2.4 -- *7)

[Note]

Definition of these measurement items is as follows:

1) Setup of Measurement Equipment

The LCD module should be turn-on to a stable luminance level to be reached. The measurement

should be executed after lighting Backlight for 20 minutes and in a dark room.

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

16

Datasheet Version.: 01

2) Definition of Contrast Ratio

CR=ON (White) Luminance/OFF (Black) Luminance

3) Definition of Luminance and Luminance uniformity

Central luminance: The white luminance is measured at the center position “5” on the screen, see

Fig.1 below. And the measure time is 30 min after discharged.

9P Luminance (AVG): The white luminance is measured at measuring points 1 to 9, see Fig.1

below.

9P Uniformity: Δ L = (L

MIN

/L

MAX

) Å~100%

4).Definition of Viewing Angle (,):

,

Upper(+)

Right(+)

Lower(-)

Left(-)

-

960 (1920,1080)

540

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

17

Datasheet Version.: 01

5) Definition of Response Time:

6) Definition of crosstalk:

CT=Y

B

-Y

A

/Y

A

X 100 (%)

Y

A :

The luminance of measured position at pattern A

Y

B :

The luminance of measured position at pattern B with Gray level 0

Pattern A Pattern B

7) Definition of Gamma (), follow VESA standard sampling every 16 gray level (0,16,32,…..224,240,255)

.(/012

Gray level (LOG)

T

%

Luminan

White

Black

90 % 90 %

10 % 10 %

Tr Tf

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

18

Datasheet Version.: 01

9. RELIABILITY TEST CONDITIONS

(1) Temperature and Humidity

TEST ITEMS CONDITIONS

HIGH TEMPERATURE

HIGH HUMIDITY OPERATION

50; 90%RH; 240h

(No condensation)

HIGH TEMPERATURE

HIGH HUMIDITY STORAGE

60; 90%RH; 48h

(No condensation)

HIGH TEMPERATURE OPERATION 50; 240h

HIGH TEMPERATURE STORAGE 60; 240h

LOW TEMPERATURE OPERATION 0; 240h

LOW TEMPERATURE STORAGE -20; 240h

THERMAL SHOCK BETWEEN -20(1hr)AND 60(1hr); 100

CYCLES

(2) Shock & Vibration

ITEMS CONDITIONS

SHOCK

(NON-OPERATIO

N)

Shock level:980m/s^2(150G)

Waveform: half sinusoidal wave, 2ms

Number of shocks: one shock input in each direction of three

mutually perpendicular axes for a total of six shock inputs

VIBRATION

(NON-OPERATIO

N)

Vibration level: 9.8m/s^2(1.0G) zero to peak

Waveform: sinusoidal

Frequency range: 5 to 500 Hz

Frequency sweep rate: 0.5 octave/min

Duration: one sweep from 5 to 500Hz in each of three mutually

perpendicular axis(each x,y,z axis: 1 hour, total 3 hours)

(3) ESD

POSITION CONDITION( MDL turn off)

Connector 1. 200 pF0 Å}250 V

2. contact mode for each pin

Module

1. 150 pF330 Å}15K V

2. Air mode, test 25 times for each test point

3. Contact mode, 25 times for each test point

(4) Low Pressure test

TEST ITEM CONDITION

Low Pressure test(storage) 260HPa (30000 ft.)324 Hr

(5) Judgment standard

The judgment of the above test should be made as follow:

Pass: Normal display image with no obvious non-uniformity and no line defect. Partial

transformation of the module parts should be ignored.

Fail: No display image, obvious non-uniformity, or line defects.

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

19

Datasheet Version.: 01

10. DESIGNATION OF LOT MARK

(a) NEW 3_IN_1 LABEL: (Model Name: CLAA215FA04)

Code Meaning Description

A Year 0~9

BC Week 01~52

DEFGH Serial No 00001~99999

I Factory T2 L WJ FDT SDT CTOC

Code R S U,V,A F Z Q

PANEL LABEL

(c) B/L MAKER LABEL ( X215FA04xxxxxxxxxxxxxxxxxxx)

(2) Location of Lot Mark

The label is attached to the backside of the LCD Module. This is subject to change without

prior notice.

A B C D E F G H I

(a)

(c) (b)

X215FA04xxxxxxxxxxxxxxxxxxx

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

20

Datasheet Version.: 01

11. PACKING SPECIFICATION

(1)Packing

10 LCD IT modules (max.) / 1 Box

24 box (max.) / 1 pallet

Box dimensions: 570(L)Å~244(W)Å~370(H)

Weight: approximately 22Kg (10 modules per box)

(2)Packing Method

Figure (a) and (b) are the packing method

Cover Protector: L1090 Å~ 50 Å~ 50mm

Pallet: 1150(L) Å~ 1000(W) Å~ 130(H) mm

Top/Bottom Cap: L1150 Å~ 1000 Å~ 130mm

Pallet stack: 1150(L) Å~ 1000(W) Å~ 1260(H) mm

Gross Weight: 538Kg(42Kg)

Figure (a) packing method

215”

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

21

Datasheet Version.: 01

Figure (b) packing method

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

22

Datasheet Version.: 01

12. HANDLING PRECAUTIONS FOR TFT-LCD MODULE

Please pay attention to the followings in handling- TFT-LCD products;

1. ASSEMBLY PRECAUTION

(1) Please use the mounting hole on the module side in installing and do not beading or wrenching

LCD in assembling. And please do not drop, bend or twist LCD module in handling.

(2) Please design display housing in accordance with the following guide lines.

(2.1) Housing case must be destined carefully so as not to put stresses on LCD all sides and not to

wrench module. The stresses may cause non-uniformity even if there is no non-uniformity

statically.

(2.2) Keep sufficient clearance between LCD module back surface and housing when the LCD

module is mounted. Approximately 1.0 mm of the clearance in the design is recommended

taking into account the tolerance of LCD module thickness and mounting structure height

on the housing.

(2.3) When some parts, such as, FPC cable and ferrite plate, are installed underneath the LCD

module, still sufficient clearance is required, such as 0.5mm. This clearance is, especially, to

be reconsidered when the additional parts are implemented for EMI countermeasure.

(2.4) Design the inverter location and connector position carefully so as not to give stress to lamp

cable, or not to interface the LCD module by the lamp cable.

(2.5) Keep sufficient clearance between LCD module and the others parts, such as inverter and

speaker so as not to interface the LCD module. Approximately 1.0mm of the clearance in

the design is recommended.

(3) Please do not push or scratch LCD panel surface with any-thing hard. And do not soil LCD

panel surface by touching with bare hands. (Polarizer film, surface of LCD panel is easy to be

flawed.)

(4) Please do not press any parts on the rear side such as source TCP, gate TCP, control circuit board

and FPCs during handling LCD module. If pressing rear part is unavoidable, handle the LCD

module with care not to damage them.

(5) Please wipe out LCD panel surface with absorbent cotton or soft cloth in case of it being soiled.

(6) Please wipe out drops of adhesives like saliva and water on LCD panel surface immediately.

They might damage to cause panel surface variation and color change.

(7) Please do not take a LCD module to pieces and reconstruct it. Resolving and reconstructing

modules may cause them not to work well.

(8) Please do not touch metal frames with bare hands and soiled gloves. A color change of the

metal frames can happen during a long preservation of soiled LCD modules.

(9) Please pay attention to handling lead wire of backlight so that it is not tugged in connecting wit

inverter.

2. OPERATING PRECAUTIONS

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

23

Datasheet Version.: 01

(1) Please be sure to turn off the power supply before connecting and disconnecting signal input

cable.

(2) Please do not change variable resistance settings in LCD module. They are adjusted to the most

suitable value. If they are changed, it might happen LCD does not satisfy the characteristics

specification.

(3) Please consider that LCD backlight takes longer time to become stable of radiation

characteristics in low temperature than in room temperature.

(4) A condensation might happen on the surface and inside of LCD module in case of sudden charge

of ambient temperature.

(5) Please pay attention to displaying the same pattern for very long time. Image might stick on

LCD. If then, time going on can make LCD work well.

(6) Please obey the same caution descriptions as ones that need to pay attention to ordinary

electronic parts.

3. PRECAUTFONSWITHELECTROSTATICS

(1) This LCD module use CMOS-IC on circuit board and TFT-LCD panel, and so it is easy to be

affected by electrostatics. Please be careful with electrostatics by the way of your body

connecting to the ground and so on.

(2) Please remove protection film very slowly on the surface of LCD module to prevent from

electrostatics occurrence.

4. STORAGE PRECAUTIONS

(1) When you store LCDs for a long time, it is recommended to keep the temperature between 0

~40 without the exposure of sunlight and to keep the humidity less than 90%RH.

(2) Please do not leave the LCDs in the environment of high humidity and high temperature such as

60 90%RH.

(3) Please do not leave the LCDs in the environment of low temperature; below -20.

5. SAFETY PRECAUTIONS

(1) When you waste LCDS, it is recommended to crush damaged or unnecessary LCDs into pieces

and wash them off with solvents such as acetone and ethanol, which should later be burned.

(2) If any liquid leaks out of a damaged-glass cell and comes in contact with the hands, wash off

thoroughly with soap and water.

6. OTHERS

(1) A strong incident light into LCD panel might cause display characteristics' changing inferior

because of polarizer film, color filter, and other materials becoming inferior. Please do not

expose LCD module direct sunlight Land strong UV rays.

(2) Please pay attention to a panel side of LCD module not to contact with other materials in

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

CPT CHUNGHWA PICTURES TUBES, LTD.,

T-3010004-008-F

CHUNGHWA PICTUER TUBES, LTD. Page:

24

Datasheet Version.: 01

preserving it alone.

(3) For the packaging box, please pay attention to the followings:

(3.1) Packaging box and inner case for LCD are designed to protect the LCDs from the damage

or scratching during transportation. Please do not open except picking LCDs up from the

box.

(3.2) Please do not pile them up more than 5 boxes. (They are not designed so.) And please do

not turn over.

(3.3) Please handle packaging box with care not to give them sudden shock and vibrations. And

also please do not throw them up.

(3.4) Packing box and inner case for LCDs are made of cardboard. So please pay attention not

to get them wet. (Such like keeping them in high humidity or wet place can occur getting

them wet.)